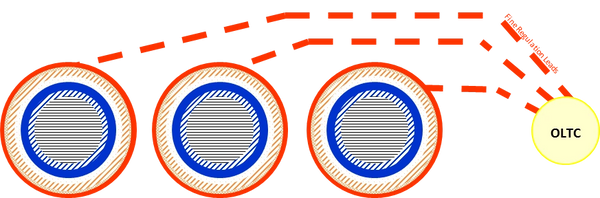

Figure 1 A sketch of a typical three-phase oil-filled power transformer

Applicable Standards

- IEC 60076-5 – Power Transformers: Ability to withstand short-circuit

- IEEE C57.12.00 – General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers

- IEEE C57.104 – Guide for Interpretation of Gases Generated in Oil-Immersed Transformers

Introduction to Transformers

Transformers are used to step up or step down supply voltages. There are two main types:

- Dry-type Transformers: Suitable primarily for indoor installations; the windings are not immersed in insulating liquid.

- Liquid-immersed Transformers: Suitable for both indoor and outdoor environments; commonly filled with insulating oil.

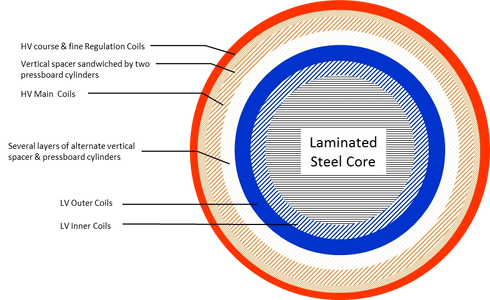

Figure 2 A sketch plan of the windings of the three-phase oil-filled power transformer

In a typical oil-filled transformer, each of the three phase windings has four layers of winding coils: two are low-voltage (LV) comprising an inner and an outer coil, and two are high‑voltage (HV) comprising a main and a coarse regulation (CR) / fine regulation (FR) coil. Each of the coils comprises many turns of copper conductors that is wrapped with paper insulation. The LV coils are housed concentrically within the HV coils and wound onto a laminated sheet steel core.

Figure 3 The internal construction of a winding phase of the three-phase power transformer

There are insulating spacers separating each individual concentric layer of LV & HV coils, constructed in cylinder pressboard sheets, and supported by vertical strips from wood. The top & bottom of each winding are stacked with wooden blocks, and there are wooden structures compressing the blocks and the windings.

In most large transformers, there is an on-load tap changer (OLTC), which automatically regulates the voltage of the transformer in the event of load variation.

Power Transformers

Are used in electricity transmission systems or at large commercial site, such as power plants & industrial plants, where there is a high demand for electricity. They are generally rated from 200MVA, with operating voltages starting at 33kV

The life expectancy of a power transformer is generally more than 20 years of service, working within conducive environments. However, unusual service conditions can reduce its life expectancy. For example, operating outside the normal ambient temperature range (-20°C & 40°C), installed at high altitude (> 1000 m above sea level) & seismic conditions.

The transformer may be fitted with a number of the following protection devices,

- Liquid level indicator, a gauge that indicates the level of the insulation liquid

- Pressure relief device, releasing excessive internal pressures that may build up during service

- Temperature indicator, measures the temperature of the insulation liquid

- Winding temperature indicator, measures the designed hottest spot in the winding

- Sudden pressure relay, an electrically operated switch that detects a sudden increase in the internal pressure of the equipment caused by a fault in the winding tank

- Buchholz relay, an oil & gas actuated relay located in the pipe connecting the winding tank & the conservator (an external overhead oil reservoir). It detects faults in the winding tank

Distribution Transformers

Step down voltage from electricity transmission systems to the level used by end-users. They are generally rated at not more than 200MVA, with operating voltages no more than 11kV

Figure 4 A sketch of a typical three-phase oil-filled distribution transformer

Rectifier Transformers

Are used in industrial processes running on direct current (dc) supply, such as dc traction, electrolysis, smelting operations & large variable speed drive trains. Power electronic circuits convert alternating current (ac) to dc, aka rectifier circuits. Power electronic circuits also convert dc to ac, aka inverter circuits. A transformer that has one of its windings connected to either a rectifier circuit or an inverter circuit is respectively known as a rectifier transformer or a converter transformer

Dry-type Transformers

Have dielectric of a gas or a solid on their windings; the windings are not immersed in an insulating liquid

Shunt Reactors & Series Reactors

(aka Steady-state reactive compensation & Current limiting reactors, respectively) Are used in electrical power systems to limit over-voltages or heavy/short-circuit current in power transmission

Shunt Reactors stabilize voltages during load variations. Long HV voltage transmission lines generate a substantial amount of leading reactive power when the supply lines are lightly loaded. Conversely, they absorb a large amount of lagging reactive power when the supply lines are heavily loaded. Without reactive power balancing, the rated voltage on the transmission lines cannot be maintained under load variations.

Series reactors protect against excessively large currents under short-circuit or transient conditions. Applications include motor starting and electric arc furnace (EAF)

Instrument Transformers

Isolate the transmission systems or mains supply circuit with the control & measuring devices, by magnetically coupling both circuits. They step down hazardous voltages or currents to a safe level for measurement or monitoring. The instrument transformers comprised current transformers & voltage transformers

Current Transformers (CT)

Couple high current lines with the monitoring devices. The primary winding of the CT is connected in series with the load current-carrying conductor. The secondary winding proportionally transforms the primary levels to typical values of 5 A for metering applications, such as wattmeters, power-factor (PF) meters, voltmeters, ammeters & relays

Voltage Transformers (VT)

(aka Potential Transformers) Reduce hazardous high voltages to a level that can be safely applied to voltmeters or protective relays. The primary winding of the VT is connected in parallel with the monitored circuit. The secondary windings proportionally transform the primary levels to typical values of 120 V, for metering applications, such as wattmeters, power-factor (PF) meters, voltmeters, ammeters & relays

Investigation of Transformer Failures

Objectives

- Verify compliance with regulatory and insurance requirements

- Assess risk of continued operation

- Identify potential commercial loss recovery

- Detect fraudulent insurance claims

Failure can cause physical damage, downtime and business interruption.

Investigation Process

- Collect all relevant data

- Visit site, review operational parameters, and gather application details

- Interview personnel familiar with the equipment

- Inspect transformer externally: record damage & perform preliminary tests

- Conduct detailed inspections of windings after untanking, ideally at manufacturer's facility

- Review & analyse operational history and available documentation

- Prepare a comprehensive investigative report

Key Considerations

- Protection device trips or alarms, repair history and abnormal diagnostic test results

- Design specifications, manufacturer details and technical drawings

- Historical performance and failures of similar transformer models

- Deviations from factory test results or standard operating practices

Dissolved Gas-in-oil Analysis (DGA)

A diagnostic technique for the detection of incipient fault conditions in oil-filled transformers, by interpreting the test results of the dielectric oil sampled from the transformer. Test results of the DGA for several years can assist in the trending of the failure mechanism of the equipment

The key gases of DGA are hydrogen (H2), methane (CH4), acetylene (C2H2), ethylene (C2H4), ethane (C2H6), carbon monoxide (CO) and carbon dioxide (CO2). With the exception of CO2, the remaining six gases are combustible. The followings are indicative signs of the individual gases,

- High carbon monoxide & carbon dioxide indicate thermal or oxidative damage to cellulose insulation. If there were high carbon monoxide detected but no reports of previous overloading events or indications of thermal problems, it could suggest excessive oxygen in the oil

- High oxygen suggests inadequate oil processing or gasket leaks

- Acetylene indicates arcing or events of very high temperatures

- High hydrogen with methane at about 1:5 ratio suggests partial discharge activity

Oil Insulation Test

Detects signs of oil deterioration including reduced dielectric strength, increased moisture & change in colour of the oil. For example,

- Reduced oil dielectric strength - possible contamination or

excessive water

- Increased moisture in oil - may be associated with excessive

water in the paper

Winding Ratio Test

Winding ratio that was different from the factory test record indicates electrical shorting of the winding. The shorting can occur between turns (aka inter-turn shorting) or between windings, such as disc-to-disc

Polarization Index (PI)

Indicates the moisture and possible deposition of conductive dust particles on the surface of insulation material. Polarization index

< 2.0 indicates deterioration of the insulation

Excitation Current Test

Detects winding problems including unintended movements caused by mechanical impact (for example, transportation) or electromotive force that was produced when supplying high current to an external short-circuit event

Partial Discharge (PD) Measurement

Detects for any localised dielectric breakdown or deposits of conductive dust particles on solid insulation of the windings

Applied Voltage (Hi-Pot) Test

Tests the insulation between two windings, or between the windings & the earthed chassis

Frequency Response Analysis

Evaluates any displacement of the transformer core, windings and the holding structures

Inspection of the Transformer Windings

Following the inspection of equipment on the site and collection of the background information, it is often necessary to inspect the internal windings of the transformer for any physical evidence of the failure. The process should be directed by a person having knowledge of the equipment. Untanking of the transformer windings is best undertaken in the manufacturer’s facility, where hoist equipment, tools for dismantling & test equipment are available to facilitate the inspection, and manufacturer’s engineers are available for discussion. Look for the following signs,

- electrical tracking or flashover marks between the windings & earthed ground

- distortion or movements of coils or windings resulting from short-circuiting

- faults between turn-to-turn

- faults between two winding coils

- conductive contaminants on the solid insulation & windings

- loose or misaligned spacers

- faults at the magnetic circuit

The steel cores are surrounded by the transformer windings and are laminated to reduce eddy-current. They concentrate the magnetic flux of the windings. Due to gaps, excessive burrs on the edges, poor maintenance or contaminated oil, the laminated steel cores can give rise to localised heating that reaches the surface, which then leads to a fault at the winding by direct contact. Signs to look for,

- electrical arcing at the laminated steel core

- leakage flux heating in the outer laminations and at joints, edges, earthed steel core & lock plates

- mechanical distortion in the laminated steel core

Common Failure Mechanisms

Transformer Tank

Winding tanks contained insulation oil, which acts primarily as an insulation medium & cooling for the windings. Leaks at the tank wall can occur due to corrosion, thermal cycling or weld cracks, resulting in the reduction of the oil level and the ingress of moisture. Insufficient cooling oil can lead to overheating of the windings

Transformer Radiators & Coolers

Occurrence of leaks can lead to the ingress of moisture, which reduces the dielectric strength of the insulation oil

Impediment to the flow of insulation oil reduces the cooling efficiency for the windings. Loss of cooling can also be associated with malfunctioning fan motors. As a result, the operating temperature of the transformer increases, which causes a corresponding decrease in the capacity of the equipment

Dielectric or Insulation Integrity

The leading cause of transformer failure is the breakdown of electrical insulation of the windings, which can result from poor installation, inadequate maintenance, defective material or deteriorating insulation due to ageing or mechanical damage associated with vibration. Oil deterioration caused by conductive particles or moisture in the oil can initiate electrical discharges, cracks, resulting in the reduction of the oil level and the ingress of moisture. Insufficient cooling oil can lead to overheating of the windings

Short-Circuiting

High level of electromotive forces in the event of a short-circuiting fault at the load circuits can lead to movements in the winding turns. In some severe situations, the winding displaces or buckles, causing abrasion to the windings’ paper insulation to the extent that conductors are exposed. Subsequently, localised arc damage can occur at one or more points of the winding turns

Transformer Bushings

Are insulating devices that allow an electrical conductor to pass safely through the grounded winding tank of the transformer. Common mechanisms that lead to bushing failures include leaks, projectiles and defective porcelain or polymer insulator. Problems of thermal instability in bushings can result in separation of seals. Deteriorated seals in terminal connections can lead to the ingress of moisture, which permeates into the oil & paper insulation, degrading the dielectric medium. Projectiles can shatter porcelain sheds

Overvoltages

Originate from external sources. Overvoltages produced by lightning activity are more significant in the vicinity thunderstorms. Overvoltages in the transmission lines are transients associated with switching operations at the power station

Load Tap Changers (LTC)

Regulate voltage levels of the transformer by either adding or removing turns from the secondary winding, thus, maintaining the desired voltage at varying loads. Problems associated with LTCs include misalignment of contacts, poor design of the contacts, high loading and component failures, which include failures of springs, bearings, shafts & drive mechanisms. Excessive wearing can cause contact failure

Copyright © 2018 efe Consultants Pte Ltd | Privacy Policy